PRODUCTS DESIGNED BY ENGINEERS FOR ENGINEERS.

Discover our wide range of application specific solutions.

MXT™

Beyond industry standard:

Tested to three times industry standard impulse criteria (600,000) and engineered to offer enhanced new wire technology and a slimmer profile for compact areas.

Increased performance:

Lighter weight for easier handling, superior performance and fuel efficiency. Lower force-to-bend ratio for faster and more ergonomic installation.

Hydraulic Tube Fittings

Minimum operating costs:

Reduced assembly time and maximum system up-time. Designed, tested and validated as a system to produce hose and coupling combinations that perform beyond any international standard.

Market Leading performance:

Complying with DIN EN ISO 8434-1 and DIN 2353, Gates Tube Fittings are important pressure transmission components for a wide range of applications.

MegaCrimp™

Exceeding expectation:

One design fits all and can accommodate many different hose system designs, on both one and two-wire meaning simplified inventory requirements. Surpassed one million impulse cycles during design testing.

Innovative, patented leak proof seal:

Gates unique "C" insert allows usage with different constructions and wall thickness, ensuring an even distribution of crimping forces to form a concentric seal.

Engineered to address evolving application challenges, meeting and exceeding multiple industry requirements and setting new standards for hydraulic hoses and couplings. Hydraulic hoses that are lighter, stronger, and more flexible than conventional hoses.

Tube Fittings with patented technology that deliver exceptional reliability and safety in extreme conditions. Continuous testing, system validation, and "made in Germany" quality ensures that these products not only meet, but exceed, performance specifications, making them exceptionally durable and high performing, even in critical applications.

Synchro-Power™ Linear

Precise Performance:

Advanced high tensile strength material for reliable and efficient operations. Parallel cord construction for uniform tensioning and smooth, low-noise operation.

Superior performance in every application:

Long lasting durability with excellent resistance to oil, chemical and water contact. No lubrication or maintenance required reducing downtime and increasing uptime.

Synchro-Power™ Flex

Custom solutions:

Helically wound cords for high power transmission drives and a variety of steel cord options and resin grades to meet specific application needs. Available in custom extruded lengths from 1.5 to 24m.

Superior performance:

Abrasion resistant for the most demanding applications, with truly endless belts offering enhanced stiffness and strength. Wide temperature ranges from -30°C to +50°C.

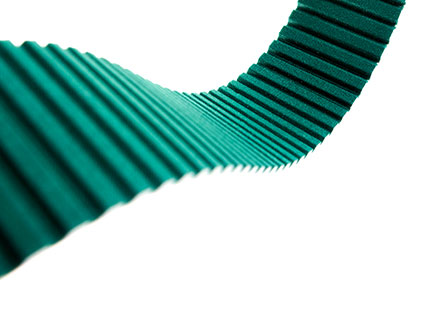

Synchro-Power™ belt with backings

Infinite design possibilities:

Reliable and durable these open ended and endless timing belts with over 30 different backing materials allow you to achieve the desired coefficient of friction, increased abrasion resistance or cushioning.

Additional surface finishing:

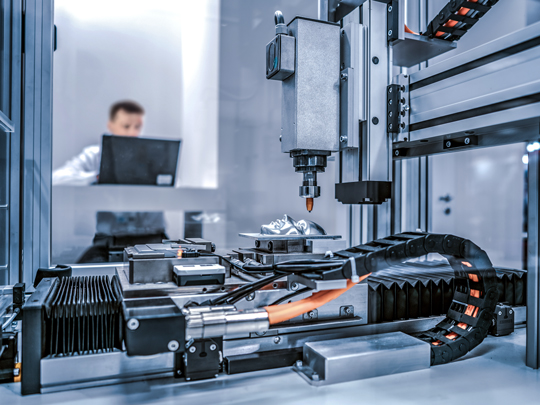

From ground edges or surfaces and tight tolerances, to punching or machining holes and slots and CNC machining of 3-dimensional contours, Gates TPU provides a range of customised solutions to achieve the required characteristic for many applications.

Available in various pitches, constructions, and tooth shapes, catering to a wide range of applications, these high-strength belts are suitable for power transmission, timing and linear applications. Lifting, pulling, and heavy load conveying, with customisation options available for diverse market needs, providing long-lasting solutions for demanding industries and applications.

PowerGrip™ GT3

Exceptional engineering:

Compact, lightweight and cost-effective drives, utilising highly advanced materials that are designed to reduce both initial, and ongoing, operating costs. High tooth jump resistance and lower running noise built into every drive.

Multiple options:

Available in 2MGT, 3MGT, 5MGT pitch - the small pitches are the optimum choice for high performance drives with high speeds, positioning and accuracy requirements.

PowerGrip™ GT4

Optimum performance:

Superior uptime, reliability and total cost of ownership. High power capacity, no lubrication and no stretching, improved safety and ergonomics, improved chemical resistance and a large temperature range – this belt has it all.

Planet and people friendly:

Made with high-performance EPDM compound PowerGrip GT4 has a reduced environmental risk and with lower noise. Rust free and no oil contaminations means it is safer for use in more applications.

Poly Chain® GT Carbon™ 5MGT

Maintenance free:

No need for constant re-tensioning and no lubrication required. Reduces costly downtime.

Superior performance:

Robust carbon tensile cord combines minimal stretch with extraordinary strength. High efficiency and accuracy positive drive. Perfect for compact applications.

PowerGrip™ HTD™ Twin Power™

Excellent Performance:

Durable, wear resistant, nylon fabric on both tooth sides provides equal high load carrying capabilities. Transmitting up to 100% of its maximum rated load from either side of the belt, these belts are designed to perform at high speeds and in extreme temperatures, with a larger tooth profile for increased performance capacity.

Reduced maintenance:

Fibreglass tensile cords provide high strength durability, excellent flex life, and high resistance to elongation. Neoprene body resists against wear from grime, grease, oil and moisture.

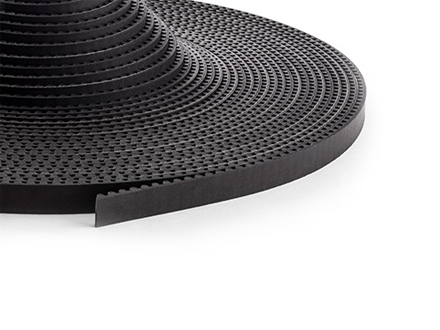

LL PowerGrip™ GT Belt

High positioning accuracy:

A comprehensive range of open-ended belts which can be easily cut to the required length. Especially suited for linear movements and accurate positioning of machine tools and X-Y co-ordinate machines.

Performance and Longevity:

High modulus tensile members ensure length stability and elastomeric body provides protection against grime, grease, oil and moisture. With no maintenance or re-tensioning required the nylon tooth facing provides a durable wear surface for long service life.

Streamlined portfolio:

Fibreglass or steel tensile cords in multiple pitches fit perfectly on GT profile pulleys and the unique straight cut construction and easy to attach clamping fixtures simplify inventory requirements.

Cutting-edge belt technology that is exceptionally durable, eliminating the need for re-tensioning and lubrication, abrasion-resistant, and chemical-resistant. These innovative belts provide a cleaner and more compact drive solution with high power capacity making them ideal for machine tool industries. Delivering improved safety, reliability and productivity where low maintenance and reliability are essential.

Quad-Power™ 4

Service Free:

High stability on the toughest drives and designed to last. Keeping your tools and mechanical equipment running longer. Maintenance free, eliminating costly downtime for re-tensioning, repair and replacement. Innovative, minimal-stretch cord technology with no tension decay in the first hours after installation, no run-in period nor any re-tensioning are required.

Innovative Materials:

Optimised notch form for reduced bending stress and improved efficiency. EPDM rubber compound ensures energy efficiencies up to 98% and a long service life with less downtime and a wear-resistant belt under extreme temperatures. Minimal-elongation polyester tensile cords allow for stable tension over the entire lifetime.

Polyflex™ JB™

Ideal design for smooth operations:

A unique belt with a distinctive 60° belt angle and ribbed top specifically designed for long life in small diameter sheave drives. Precisely designed for compact drives with high-speed ratios that require especially smooth operation.

Joined Belts:

Unique configuration, two, three or more belts joined together to provide extra stability and improved performance. This joined belt style can be used instead of matched single belts making Polyflex JB belts ideal for milling, grinding or drilling machines, lathes, machine spindle drives and many other machine tool applications.

Micro-V®

Superior Performance:

The tips of the “V” are truncated giving the new Micro-V belts increased flexibility, reduced heat build-up and allowing them to operate at extra high speeds on smaller diameter sheaves.

Low Maintenance:

Gates Micro-V are extremely smooth running and highly resistant to oil, heat and other adverse conditions. The belts last longer than alternatives to keep your tools and mechanical equipment running longer.

Predator™

Market Leading V-belts:

Unique in their robustness and high load carrying capability they are unrivalled. Excellent problem-solving solutions that perform well in extremely demanding applications. The highest power density and virtually zero stretch because of the use of high strength, high modulus aramid tensile cords.

Minimal downtime:

No need for constant belt re-tensioning meaning less maintenance and less downtime. Double fabric cover offers extreme abrasion and wear resistance. Improved rubber compounds provide superb oil and heat resistance for lower TCO.

Offering exceptional efficiency, compact design, and reduced maintenance costs. These robust, high-load capacity belts are ideal for use on machines and machine tools requiring high performance and smooth operation in limited space, such as bench type milling machines, lathe drives, metal working machine spindle drives and computer peripheral equipment, resulting in significant cost savings and improved design flexibility across a multitude of industrial applications.